HillTip IceStriker™ Light Truck Salter & Sander 1600 A/CM

|

|

|

Specifications

|

Model |

1600 A/CM

|

Category Name |

Snow Equipment

|

Year |

2025

|

|

Sale Type |

New

|

Manufacturer |

HillTip

|

Odometer |

km

|

|

Vehicle |

4,5-12 ton trucks

|

Material |

Salt, sand, granulat/mixed (max 8mm ∅ with auger)

|

Spinner Size |

500 mm

|

|

Weight (empty) |

360 kg*

|

Spreading Width |

1-8 m (may vary depending on material)

|

Capacity, Struck |

1500 l

|

|

Capacity, Rounded |

1600 l

|

Hopper Construction |

Poly

|

Minimum Truck Bed Length |

2150 mm

|

|

Conveyor Belt/ Chain Width |

300 mm

|

Auger Diameter (stainless Steel) |

150 mm

|

Total Length (including Spinner) |

A: 3000 mm, CM: 2900 mm

|

|

Maximum External Width (with Tarp Mounted) |

1750 mm

|

Total Height Of The Hopper From The Loading |

1250 mm

|

Price |

Contact for price CAD

|

| |

|

|

|

Description

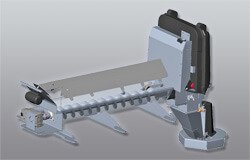

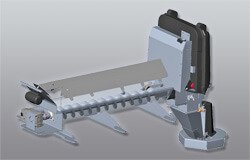

TRUCK SALTER AND SANDER DESIGN

The Hilltip IceStriker™ 1600-2600 is a 12V/24V electric sand and salt spreader designed for 4.5-12 ton trucks. Whether you choose the auger or chain as your feed mechanism, this spreader accommodates both. Constructed with a lightweight poly hopper and mounted parts in stainless steel, it guarantees effective protection against corrosion. This exceptional sand and salt spreader for trucks and its advanced STRIKESMART™ control & tracking system help you save money and minimise environmental impact while ensuring powerful de-icing results.

|

LIQUID DE-ICING FUNCTIONS AND TRUCK-MOUNTED BRINE SPRAYER

You can effortlessly transform your sand and salt spreader into a complete liquid-deicing spreader or a pre-wet combi salt spreader. The integrated tanks in the double-walled hopper body can store up to 900 litres of liquid. This spreader can be equipped with a 2-metre spray bar or a hose reel, complemented with a handheld spray nozzle for those needing a truck-mounted brine sprayer.

|

|

|

|

STANDARD FUNCTIONS AND ACCESSORIES

|

STANDARD_FUNCTIONS_AND_ACCESSORIES

COLOR SCREEN CONTROLLER COLOR SCREEN CONTROLLER

The controller lets you customize your spreading session according to your current situation. Automatic GPS speed control adjusts the amount of spreading material (g/m2) according to your vehicle speed, while manual mode lets you insert a fixed auger speed. The controller additionally collects and saves essential data to an USB memory, allowing you to generate spreading reports. The controller also makes it easy to turn on functions, like vibrator, beacon and work light, from inside the cabin.

|

FLIP UP CHUTE FLIP UP CHUTE

Stainless steel flip-up chute, designed for spreading salt with high humidity

|

12/24V ELECTRICAL MOTORS

12 V (standard) or 24 (optional) volt dual motors, mounted inside a sealed weather-resistant enclosure.

|

VIBRATOR

Vibrator prevents bridging and de-icing material from clogging by shaking the inverted Vee.

|

INVERTED V

Inverted-V helps reduce heavy start-up loads on the auger/conveyor. All in stainless steel.

|

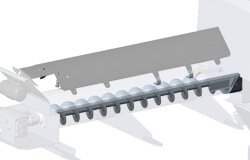

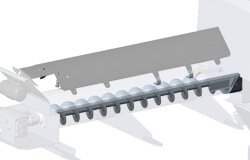

FEED MECHANISM – AUGER OR CHAIN FEED MECHANISM – AUGER OR CHAIN

Choose the feed mechanism you prefer: auger, conveyor belt or conveyor chain. Image shows the 150 mm stainless steel auger.

|

BUILT-IN TIE-DOWN LOOPS

Built-in tie-down loops for strapping unit to truck

|

TOP SCREEN TOP SCREEN

Top screen prevents rocks and big material chunks from getting into the hopper

|

|

|

OPTIONAL FUNCTIONS AND ACCESSORIES

|

OPTIONAL_FUNCTIONS_AND_ACCESSORIES

END OF MATERIAL ALARM SENSOR END OF MATERIAL ALARM SENSOR

End of material alarm sensor on spinner

|

REAR & INDICATOR LIGHTS REAR & INDICATOR LIGHTS

Rear & indicator lights for improved visibility

|

HOSE REEL HOSE REEL

12m hose reel for spraying hard-to-reach areas

|

SPRAY BAR SPRAY BAR

2m wide spraybar with 2-5m spraying width

|

ACCESSORIES

- License plate kit

- Warning lights / LED Strobe lights

- 24V motors and control system

- Adjustable work light at the rear of the spreader for improved visibility

- Leg stand for practical storing and easier removal and installation

- Optional color: orange

- Adjustable spreading symmetry from inside the cab

- Extended chute for truck bed height over 120 cm

- Extended auger/conveyor for optimization of vehicle axle loading.

|

LIQUID FUNCTIONS

- Pre-wet salt liquid kit, nozzles, pump with built-in tanks in spreader construction

- Bladder tank stores additional liquid inside hopper

- Built-in salt liquid level check for optional liquid system, which also includes an electronic sensor.

|

|

|

LITERATURE

|

|

|

TOP SCREEN

TOP SCREEN END OF MATERIAL ALARM SENSOR

END OF MATERIAL ALARM SENSOR REAR & INDICATOR LIGHTS

REAR & INDICATOR LIGHTS HOSE REEL

HOSE REEL SPRAY BAR

SPRAY BAR