SnowEx® 12140

ADVANCED SALT DELIVERYThe HELIXX™ 0.7 cu yd stainless steel hopper spreader is right sized for today’s most popular half-ton and light-duty trucks. Like the full-sized HELIXX units, this model provides excellent material flow, but in a more compact size that’s better suited to handle smaller spaces and jobs. |

|

|

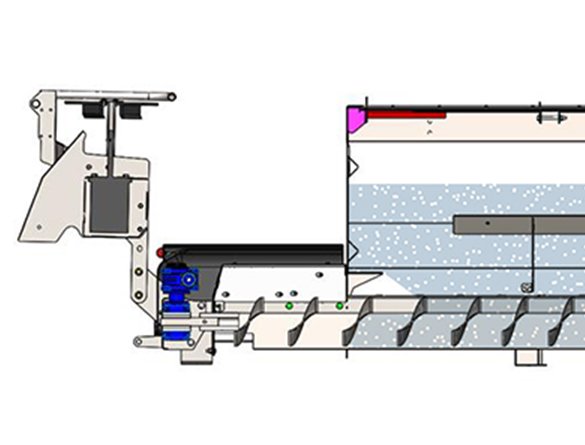

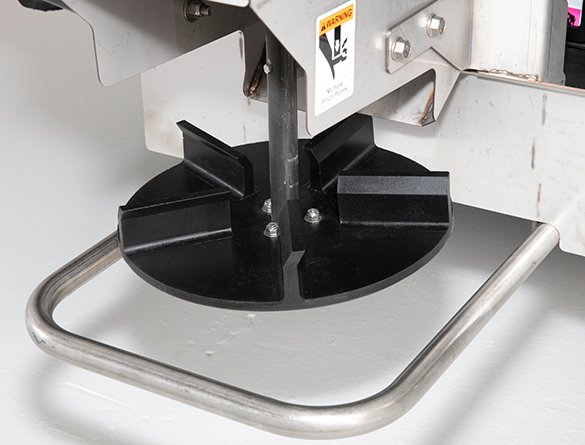

ADVANCED SALT DELIVERYThe patent-pending corkscrew – or “helix” – design of the HELIXX material delivery system is optimized for efficient and cost-effective use of salt and was designed to operate in the target range for salt spreading best practices. The innovative design helps prevent clogs and delivers a material flow superior to traditional augers. |

CAB FORWARD DESIGNThe cab forward hopper delivers better payload distribution to reduce stress on the truck and prevents leakage/spilling when transporting. |

|

|

STAINLESS STEEL CONSTRUCTIONHopper and frame are constructed of corrosion-resistant stainless steel. The frame features a unique leg and sill design to form a ridged backbone structure for greater durability, and riveted construction provides consistent, quality joints. |

STAINLESS STEEL CONSTRUCTIONThe hopper and frame are constructed of corrosion-resistant stainless steel. The frame features a unique leg and sill design to form a ridged backbone structure for greater durability. |

FLIP-UP/REMOVABLE CHUTERemove a single pin to flip-up the chute, or two pins to take it off entirely, for easy hitch access and more flexible storage. Molded spinner plug must be removed when flipped for dumping. |

ACCESSORY INTEGRATIONConveniently connect accessories directly into the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the vehicle. |

SPINNER HEIGHT ADJUSTMENTThree spinner height adjustments allow spreaders to achieve a consistent spinner height of 18 to 22 inches off the ground, regardless of vehicle type (Standard on 11920, 11930 and 11940 models). |

DUAL VARIABLE-SPEED CONTROLAllows for variable control of spinner and HELIXX system speeds for precise material delivery, whether at low or high output. Features auto reverse and integrates with accessories (including pre-wet and direct liquid application). |

DUMP SWITCH & WORK LIGHTBy using the two rear mounted conveyor dump switches, operators can safely offload material or fill walk-behind spreaders. A third switch is also provided so that an accessory work light my be conveniently controlled from not only the cab but also the rear of the hopper. |

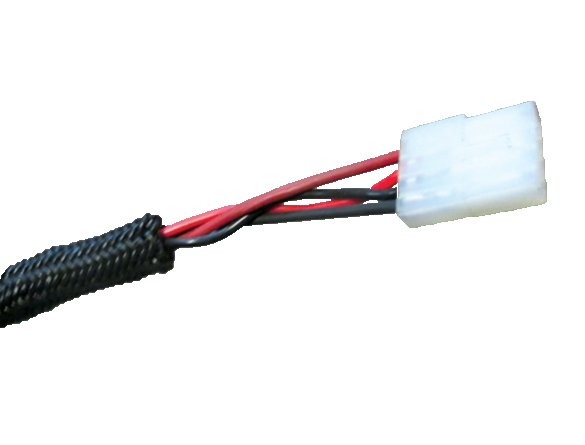

SIMPLE INSTALLATIONOnly requires a single 4-pin wire routed into the cab to install the compact control. |

FLEET FLEXThe FLEET FLEX electrical system provides a consistent electrical platform and complete fleet interchangeability between all HELIXX spreaders. |

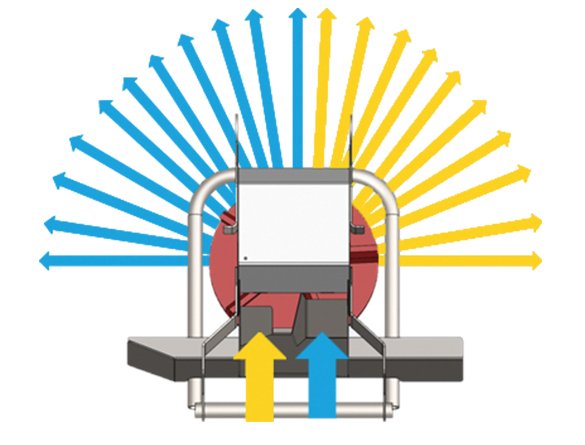

SPINNERAn extra large 12" polyurethane spinner delivers a spread pattern of up to 30' and provides long-lasting, corrosion-free performance. |

TOP SCREENTop screen ensures material that enters the hopper is consistent size by breaking up any large clumps and filters out large debris to ensure proper operation. |

NO-BLAST STARTUPFor maximum material placement and control, the spinner doesn’t blast upon startup, instead starting at the desired speed setting on the dial. |

REAR-MOUNTED GEAR BOXEasy access to motors, drives and other key components maximizes serviceability. |

ACCESSORY KNOCK-OUTSHoppers feature knock-out holes for plug and play integration of certain accessories. |

PRE-WET AND DIRECT LIQUID APPLICATIONTriple Threat The HELIXX 0.7 cu yd stainless steel spreader is a triple threat—with the ability to spread, pre-wet or spray. By adding pre-wet tanks, a pump and a spray kit, the spreaders not only can pre-wet materials, but they can also be used for spraying brine directly onto the driving surface for anti-icing applications. |

| Name | Link |

| Snowplows Brochure | Download |